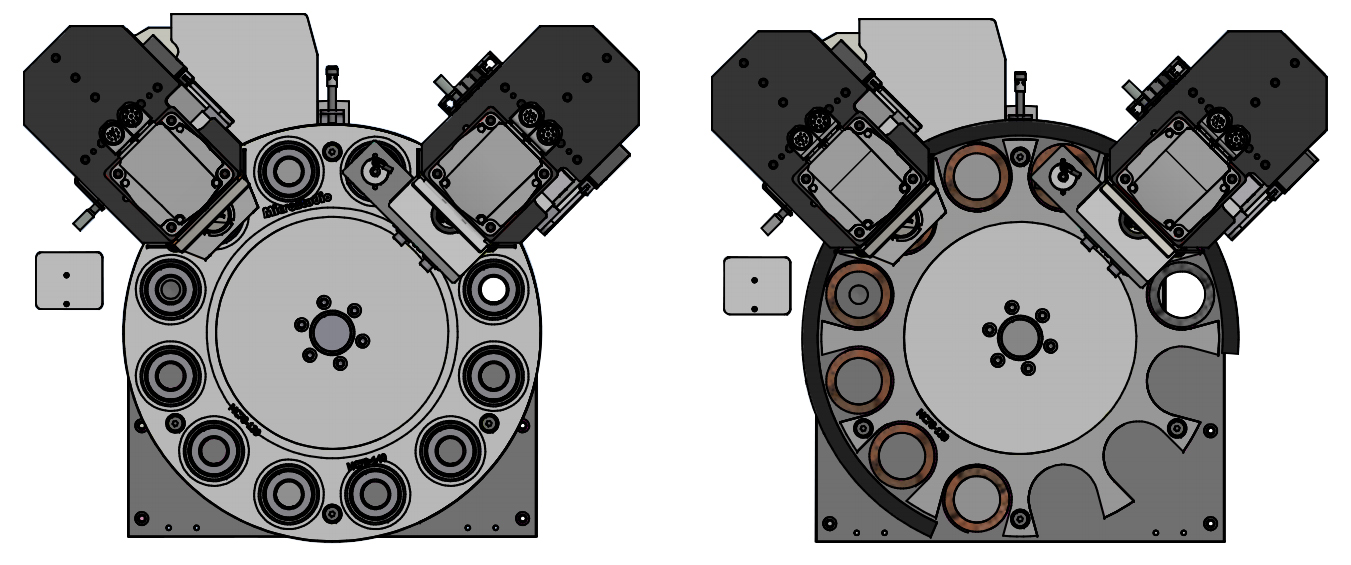

MC54-1000-LX-021

Setting and load testing machine for wave and cup springs

This control machine is built with an optimized structure to work with minimum strokes and high loads.

It can be loaded manually or with a feeder and a special loader designed to avoid the overlapping of parts and prevent the loading of overlapped ones, “coupled” pieces.

Then, the pieces can be loaded from the above or laterally, depending on their geometry.

Setting: the setting station is equipped with a shock absorber which allows an efficient and fast setting at length or at solid height.

Measurement: millesimal positioning (0.001 mm) that allows good precisions even with this type of very rigid springs.

This machine carries out controls of the loads, lengths, and rigidity obtained by the force / length curve.

Measures can be done both ways, compressing or releasing the spring

Software: it stores all the setting and control parameters and integrates the management of the loader.

Robustness: high hardness anti-wear material and anti-jamming and overlapping systems.

For any further information do not hesitate to contact our sales offices at the email address: info@microstudio.eu

Setting: the setting station is equipped with a shock absorber which allows an efficient and fast setting at length or block.

Measurement: millesimal positioning (0.001 mm) that allows good precisions even with this type of very rigid springs.

This machine carries out controls of the load, lengths, and rigidity measures by the construction of the force graph both in compression and release.

Software: it stores all the setting and control parameters and integrates the management of the loader.

Robustness: high hardness anti-wear material and anti-jamming and overlapping systems.

For any further information do not hesitate to contact our sales offices at the email address: info@microstudio.eu